It is a traditional and advanced 38 punched forming machine for hard candy. Capacity range 200-400kg/h, synchronous automatic control, fulling, sizing and forming.

different shapes of candies can be made via chang-over of the molds

| Model | W400 |

|---|---|

| Capacity | 300-400kg/h |

| Steam Pressure | 0.5~0.8mpa |

| Voltage | 300kw/380V |

| Length of Production Line | 16m |

The lollipop production line including the melting pot, storage tank, vacuum cooker, cooling bed, batch roller, rope sizer, forming machine, cooling cabinet.

| Model | W-400 |

| Capacity(kg/h) | 200-400 |

| Candy Weight Range | 2-7g |

| Steam Consumption(kg/h) | 250-400 0.5~0.8mpa |

| Air Compressor | 0.2M³/min

0.4-0.6mpa |

| Working Temperature(℃) | 20~25 |

| Working Humidity(%) | 55 |

| Total Power(kw) | 38 380kw |

| Total Length(m) | 16 |

| Weight | 8000kg |

The details:

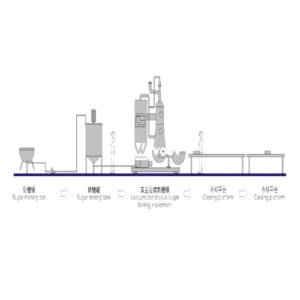

General Layout:

1. Melting pot:

Putting the sugar, glucose, and water into the tank and heating them to 120 degrees, thermostat equipped with the machine.

Stirring with scrap blade, mixing the syrup evenly. Pull up the top pole when finished and the syrup will flow out to the storage tank via the motor.

Electric, gas, or steam pots are available for you.

2. Storage Tank:

The melted syrup goes into the storage tank via the motor and the three-way valve. Once finished, pull up the top rod, and the syrup will go to the next part under the motor function

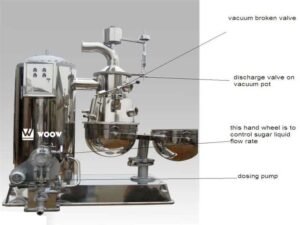

3. Vacuum Cooker:

Recook the syrup to 140 degrees for reducing the syrup moisture. only 5 minutes for each batch.

4. Cooling Conveyor:

The surface plate is the jacket layer, cooling water goes through the inlet and outlet tubes which connecting with the cooling water box.

5. Batch Roller:

An electric heater is attached along with a Batch Roller machine to keep the candy mass warm according to requirement.

The roller gap can be adjusted.

Including four rollers, transmission case, lifter, holder, and adjuster.

6. Rope Sizer:

The candy dough goes into the 5 pairs rope sizer for making thinner dough for hard candy.

The heating equipment is installed under each wheel to keep the dough soft.

7. Hard/Lollipop Candy Forming Machine:

Die-formed hard candy and lollipop made by this machine with even size, less wastage, and lower noise.

Running speed can be adjusted, and the center-filled jam, the powder also can be produced.c

8. Cooling Line:

Adopting the swing arm of CAM crank vibration mode, transferring the candy into the cabinet.

The cooling air evenly, and no broken surface, no stick on the conveyor.

9. If you want to make top-class hard candy, it is better to add the white-pulling and kneading machine.

10. Packing in a wooden box:

We will contact you within 1 working days, please pay attention to the email with the suffix“@woowmachinery.com”

Note: Your email information will be kept strictly confidential